A I-Manual Log Splitter Ingabe impahla ehlonishwayo yabenzi bezindlu ezishisa ngokhuni noma ukujabulela i-firepit yokuzijabulisa. Ukulula kwayo, ukuntuleka kokuthembela kuphethiloli noma ngogesi, futhi ukwakhiwa okuqinile kuyizinzuzo ezinkulu. Kodwa-ke, umbono wokuthi la mathuluzi alulame ngokuphelele - umbono ongemuhle ojwayelekile. Ngenkathi ngokungangabazeki ukunakekelwa okuphansi kunabalingani babo abanamandla, inqubo yesondlo engaguquki futhi ephelele yesondlo iyinto ebaluleke kakhulu ekuqinisekiseni impilo yakho ende, ukuphepha, kanye nokwenza. Kugcinwe kahle I-Manual Log Splitter Ungasebenzela umnikazi wayo ngokuthembekile amashumishumi eminyaka, kuyilapho onganakwa angaba yingozi yokuphepha noma umthombo wokukhungatheka.

Ukuqonda Izingxenye Eziyisisekelo Zokulondolozwa Okusebenzayo

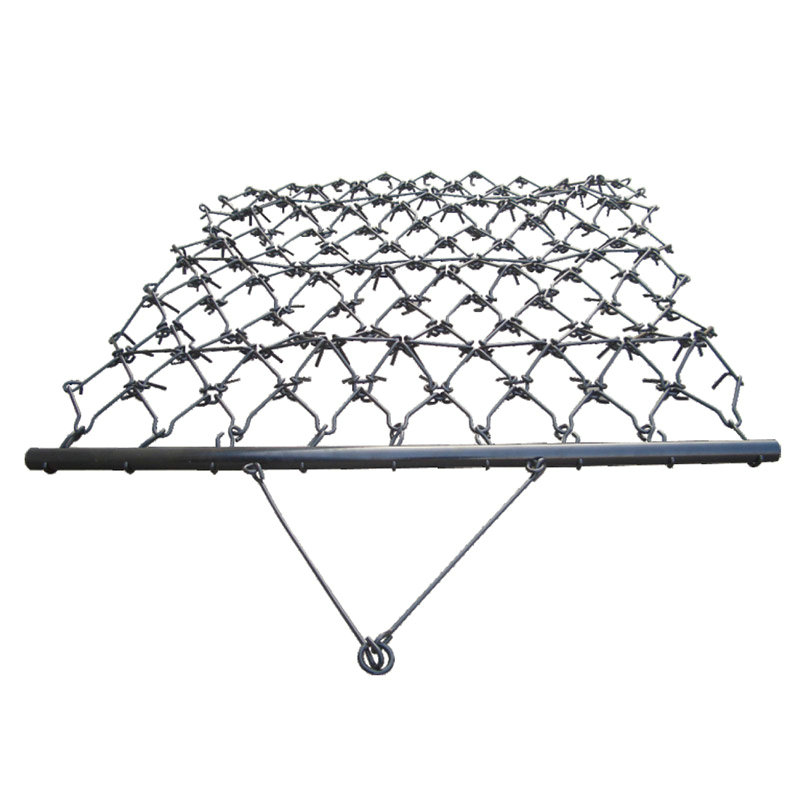

Ngaphambi kokuphuza emisebenzini ethile yokulungisa, kubalulekile ukuqonda izingxenye ezisemqoka zokujwayelekile I-Manual Log Splitter . Izinhlobo ezahlukahlukene zikhona, ezinjengamamodeli we-hydraulic jack, amamodeli we-kinetic I-Flywheel, kanye neziqhekeza zohlobo lwesikulufa, kepha iningi labelana ngezinto ezijwayelekile. Ukwazi umsebenzi wengxenye ngayinye kuzokusiza uqonde ngobani Isinyathelo ngasinye sesondlo siyadingeka nokuthi yini okufanele uyibheke ngesikhathi sokuhlola.

Isakhiwo esiyisisekelo yi- uphahla noma usebe lokukhanya , enikeza isisekelo namandla kuwo wonke umshini. Le khasi shaya yiphuzu lensimbi oluqinile elenza ukuqhekeka kwangempela kwezinkuni. Kumamodeli we-hydraulic, a isilinda se-hydraulic iqhutshwa isibambo sepompo ukusunduza ukungena ngemvume ku-wedge noma i-wedge ku-log. Lolu hlelo lugcwele uketshezi lwe-hydraulic futhi uthembele ochungechungeni lwe izimpawu nama-o-rings ukuqukatha ingcindezi. Le khasi Khipha i-valve Ilawula ukukhishwa kwesilinda. Amamodeli we-kinetic afaka a flywheel , shayela amagiya , no rack ne-pinion uhlelo olugcina futhi lukhipha amandla. Ekugcineni, wonke amamodeli anayo izingxenye ezinyakazayo njengezikhonkwane ze-pivot, ama-bushings, kanye neziphethu ezidinga ukunakwa. Ukubona lezi zinto kuzokwenza izinqubo zokugcina ezilandelayo zinembile futhi ziphumelele.

Ukuhlolwa kwangaphambi kokusebenzisa nokuthambisa

Ukuhlolwa okufushane kokusetshenziswa kwangaphambili kungumugqa wokuqala wokuvikela ngokumelene nokuphuka okungalindelekile nezinkinga zokuphepha. Le nqubo kufanele ithathe imizuzu embalwa kuphela kepha ingavimbela ukulungiswa okubizayo nezingozi. Kungumkhuba obalulekile ukuthuthukisa noma ngubani osebenza a I-Manual Log Splitter .

Qala ngokuhlola okubukwayo komshini wonke. Bheka noma yiziphi izimpawu ze imifantu, ukugoba, noma ukugqwala okuphambili ku-main main nohlaka. Lokhu kungakhombisa ubuthakathaka besakhiwo. Hlola konke ama-bolts, amantongomane, kanye nama-fasteners ukuqinisekisa ukuthi baqinile; Amandla amakhulu akhiqizwa ngesikhathi sokuhlukaniswa angakhulula ngokushesha. Hlola umshado nganoma yiziphi izimpawu zomonakalo noma ukugqoka ngokweqile; I-wedge ye-conped noma ekhubazekile izosebenza kangako futhi ibe yingozi kakhulu. Amamodeli we-hydraulic, funa noma yiziphi izimpawu ezibonakalayo ze uketshezi lwe-hydraulic leaks ezungeze isilinda, iphampu, nama-hoses. Ngisho nokuvuza okuncane kungakhombisa uphawu oluhlulekayo oluzobe lubi ngokuhamba kwesikhathi. Kwamamodeli we-kinetic, aqinisekise ukuthi unogada we-flywheel uvikelekile nokuthi indlela yokushayela imahhala ekuvinjelweni okunjenge-chips yokhuni nokungcola.

Umsebenzi obaluleke kakhulu wokusebenzisa kwangaphambili uvame ukuthambisa. Faka amaconsi ambalwa wamafutha omshini wokukhanya kuwo wonke amaphuzu abonakalayo e-pivot namalunga ahambisanayo. Lokhu kufaka phakathi ukuxhumana nesibambo sepompo, amaphuzu we-pivot wendlela yokukhishwa kwe-valve, nanoma yiziphi ezinye izindawo lapho insimbi iqhubekela khona ngensimbi. Lesi sinyathelo esilula sinciphisa ukungqubuzana, sinciphise ukugqoka, futhi senze ukusebenza kwe I-Manual Log Splitter bushelelezi ngokusobala. Kuyasiza nokuvikela lezi zingxenye ekugqwabeni. Musa ukugcoba ngokweqile, njengoba uwoyela ngokweqile kungaheha uthuli kanye ne-grit, kwakha ukunamathisela okuhlukumezayo.

Ukuhlanza okusetshenziswayo kokusebenzisa nokunakekelwa

Umsebenzi wokugcina owakho I-Manual Log Splitter ayiphelele uma ilogi lokugcina lihlukaniswe. Ukunakekelwa kokusetshenziswa kwangemva kokubaluleka kubaluleke kakhulu kunesheke lokusetshenziswa kwangaphambi kokusetshenziswa, njengoba likhuluma ngokugqokwa nokungcoliswa okwenzeka ngesikhathi sokusebenza. Ukuthatha imizuzu embalwa ukuhlanza leli thuluzi kuzokhokha izinzuzo ezibalulekile empilweni yayo yenkonzo.

Ngemuva kokusebenzisa, i-splitter izombozwa kuma-chips okhuni, ku-sap, kanye nomswakama. Sebenzisa ibhulashi elukhuni ukususa yonke imfucumfucu yezinkuni kusuka ku-beam, wedge, naku-ndimba noma izindlu ze-flywheel. I-Sap i-acid futhi ingakhuthaza ukugqwala, ngakho-ke kuyalulekwa ukusula indawo yensimbi nge-rag. Uma i-SAP yakha, i-degreaser ye-biodergradable ingasetshenziswa kancane, kepha qiniseka ukusula indawo eyomile ngemuva kwalokho. Kubalulekile ukugcina I-Manual Log Splitter endaweni eyomile, embozwe, njenge-shed noma egalaji. Ukushiya kwalo ngaphandle kuvezwa izinto ezizosheshisa ngokushesha ukugqwala nokugqwala, ukwehlisa ubuqotho nokusebenza kwesakhiwo nokusebenza kwethuluzi. Uma kufanele uyigcine ngaphandle, zitshale isembozo esindayo, esingenamanzi. Ngaphambi kokugcina, qiniseka ukuthi i-splitter yomile ngokuphelele futhi iphinde iphinde ithole isilinda se-hydraulic ngokuphelele kumamodeli lapho lokhu kungenzeka khona ukuvikela inqama kusuka ekugqwaleni.

Ukunakekelwa ngezikhathi ezithile kanye nokunakekelwa kohlelo lwe-hydraulic

Ngenkathi imishini yangaphambi kwangaphambi nangemuva ibalulekile, kudingeka uhlelo lokugcina olujulile lwesikhathi sokubhekana nezinto ezingadingi ukunakwa konke ukusetshenziswa okukodwa. Lokhu kunakekelwa ngezikhathi ezithile yitshe lokuthenjwa kwesikhathi eside kwe I-Manual Log Splitter .

Kumodeli ye-hydraulic, umsebenzi obaluleke kakhulu wesondlo wokuhlola ubheka futhi ushintsha uketshezi lwe-hydraulic. Ngokuhamba kwesikhathi, uketshezi lungangcoliswa ngomswakama nezinhlayiya zensimbi, ukulahlekelwa yizakhiwo zalo zokugcoba kanye nokulimaza amaphampu nezimpawu. Thintana nencwajana yomnikazi wakho ngohlobo oluthile nesisindo soketshezi esinconyiwe, njengokusebenzisa uhlobo olungalungile kungadala ukulimala. Inqubo ejwayelekile ifaka ukubeka i-splitter ebusweni bezinga, ukuthola ipulaki yokugcwalisa i-reservoir, nokuhlanza indawo eyizungezile ukuvikela ukungcoliswa. Bheka izinga lamanzi; Uma kuphansi, kuya phezulu. Uma uketshezi lubonakala lumnyama, lumkhulu, noma lunephunga elishisiwe, yisikhathi soshintsho oluphelele. Lokhu kuhilela ukudonsa uketshezi oludala, kugcwaliswe uhlelo uma kungenzeka, futhi kugcwaliswe ngoketshezi olusha. Le nqubo yigama elibalulekile lokusesha kwabanikazi: Ungashintsha kanjani uketshezi lwe-hydraulic ku-brain log splitter .

Zonke izinhlobo ze I-Manual Log Splitters dinga ukunakwa ngokucophelela ezakhiweni zabo eziphakeme kakhulu. Ngezikhathi ezithile, kufanele uqhube ukuhlolwa okuphelele kwe-wedge, uqinisekise ukuthi ayikakhuli ku-beam noma alimale. Bheka izikhonkwane ezigqokwa ama-pivot kanye nama-bushings; Noma yimuphi umdlalo obalulekile kulawa malunga angathinta ukusebenza nokuphepha. Kumamodeli we-kinetic, hlola amagiya kanye ne-rack nganoma yiziphi izimpawu zokukhipha noma ukugqoka okungajwayelekile. Intwasahlobo kwamanye amamodeli wezandla kufanele ihlolwe ukukhathala noma ukuqhekeka. Ukuqinisa yonke i-bolt kanye ne-fastener emshinini ngamathuluzi afanele ngalesi sikhathi sokuhlola ngezikhathi kuwukuzijwayeza kakhulu.

Ithebula elilandelayo libonisa uhlelo lokulondolozwa oluphakanyisiwe:

| Umsebenzi onikeziweyo | Ubuningi bokwenzeka | Isenzo esikhulu |

|---|---|---|

| Ukuhlolwa Okubonakalayo | Ngaphambi kokusetshenziswa ngakunye | Bheka imifantu, ama-bolts okuxekethile, kanye nokuvuza kwe-hydraulic. |

| Gcoba amaphuzu e-pivot | Ngaphambi kokusetshenziswa ngakunye | Sebenzisa uwoyela okhanyayo kuwo wonke amalunga ahambayo. |

| Ukuhlanza Okujwayelekile | Ngemuva kokusetshenziswa ngakunye | Hlikihla imfucumfucu bese usula izindawo. |

| Hlola izinga le-hydraulic fluid | Njalo amahora angama-10-20 wokusebenzisa | Phezulu nge-fluid efanele uma kuphansi. |

| Hlola wedge nohlaka | Njalo amahora angama-25-50 wokusebenzisa | Funa ukulimala, ukugqoka, nokuqinisekisa ama-fasteners aqinile. |

| Shintsha uketshezi lwe-hydraulic | Njalo ngonyaka noma wonke amahora angama-50-100 | Hlikihla bese ubeka uketshezi lokuvimbela ukulimala kwangaphakathi. |

| Isheke eliphelele le-bolt | Semi-minyaka yonke | Qinisa ngokuhlelekile wonke ama-fasteners emshinini. |

Ukuxazulula inkinga izindaba ezijwayelekile

Noma ngenqubo yesondlo ekhuthele, kungavela izingqinamba. Ukwazi ukuthola futhi ukubhekana nezinkinga ezijwayelekile kuzokonga isikhathi nemali. Ukuqonda lezi zinyathelo zokuxazulula izinkinga kuyingxenye yokuba nesibopho I-Manual Log Splitter ubunikazi.

Enye yezinkinga ezivame kakhulu ngamamodeli we-hydraulic a Ukulahleka kwamandla . I-splitter ibonakala isebenza kepha izitebele ezikulongeni kufanele zihlukaniswe kalula. Imbangela evame kakhulu yi-Hydraulic fluid ephansi. Umoya ohlelweni ungabangela nokusebenza okubucayi noma okubuthakathaka; Lokhu kuvame ukudinga ukuhamba ngebhayisekili amasilinda amahlandla ambalwa ngenkathi kuhlanganiswa ngoketshezi ukususa umoya. If the fluid is full and the system is bled, the problem may be contaminated or degraded fluid, or in worse cases, worn internal pump components or seals. Omunye umbuzo ojwayelekile I-Manual Log Splitter cylinder won’t retract . Lokhu cishe kuhlobene njalo ne-vveve yokukhishwa. Kungavinjwa ngemfucumfucu, noma indlela uqobo lwayo ingahle ibambeke noma yonakele. Ukuhlanza ngokucophelela indawo ye-valve futhi kuqinisekiswe ukuthi isibambo sihamba ngesinyathelo sokuqala.

Kuzo zonke izinhlobo, ubunzima ekusebenzeni buvame ukulandelela emuva ekuntulekeni kokuthambisa. Uma isibambo sepompo silukhuni noma i-flywheel kunzima ukuzibandakanya, hlola ukuthi wonke amaphuzu e-pivot anamafutha kahle. Umsindo wokugaya ophikelelayo ovela kumodeli ye-kinetic ungakhombisa inkinga ngamagiya noma i-rack, edinga ukuhlolwa okuningiliziwe. Khumbula, ukuphepha kubaluleke ngesikhathi sokuxazulula inkinga. Ungalokothi uzame ukuhlukanisa uhlelo olucindezelwe lwe-hydraulic noma umsebenzi ohlelweni lwe-kinetic ngaphansi kwengxabano ngaphandle kolwazi olufanele namathuluzi.

Ukugcina isikhathi eside nokuvimbela ukugqwala

Uma uhlala esimweni sezulu esihlukile ngesizini yokhuni ehlukanisayo, ulungiselela okwakho I-Manual Log Splitter Ukuze isitoreji sesikhathi eside iyinqubo ebalulekile. Ukulondolozwa okufanele kuvimbela ukonakala ngezikhathi zokungasebenzi, ukuqinisekisa ukuthi ithuluzi lilungele ukusetshenziswa ngokushesha lapho lidingeka futhi.

Umgomo wokulungiselela ukugcinwa ukuvikela ithuluzi ezitheni zalo ezimbili ezinkulu: umswakama nothuli. Qala ngokuhlanza ngokuphelele, njengoba kuchaziwe esigabeni sokunakekelwa kwangemva kokusetshenziswa, kepha kucace ngokwengeziwe. Susa yonke iminonjana ye-SAP nezinkuni zezinsalela. Lapho i-splitter ihlanzekile futhi yomile ngokuphelele, faka ukuhlanganiswa okuvikelayo kuyo yonke indawo yensimbi eveziwe ukuvikela ukugqwala. Amafutha akhanyayo noma isifutho sokuvimbela ukugqekeza esikhethekile silungele lokhu. Sula ifilimu elincanyana phezu kogongolo, umshado, isilinda se-cylinder, nanoma yiziphi ezinye izingxenye zensimbi ezingatholakali. Ungakhohlwa ngaphansi komshini.

Kumodeli ye-hydraulic, kunconywa ukugcina iyunithi nge-cylinder yabuyiselwa ngokuphelele. Lokhu kuvikela induku yepiston ebekiwe evela ekugcekeni nasekulimaleni kwemvelo. Gcina I-Manual Log Splitter endaweni eyomile, embozwe. Ukuyibeka kuma-pallets noma emabhuloki ukuze kugcinwe ngaphandle kokhonkolo kungasiza kakhulu ukunciphisa othintana nomswakama. Gwema ukuyigcina ngaphansi kwenqwaba yeminye imishini lapho umswakama ungabanjiswa khona futhi umoya awukwazi ukujikeleza. Ukuthatha lezi zinyathelo kuzogcina ubuqotho nokubukeka kwethuluzi lakho iminyaka.

Isixhumanisi esibucayi phakathi kwesondlo nokuphepha

Akunakwenzeka ukuxoxa ngokulondolozwa kwe I-Manual Log Splitter Ngaphandle kokugcizelela ukuxhumana kwayo okuqondile nokujulile ekuphepheni kokusebenza. Ithuluzi eligcinwe kabi yithuluzi elingaphephile. Amabutho aphezulu abandakanyeka ekuqhekekeni kwezinkuni angaguqula udaba oluncane lwesondlo lube yingozi enkulu.

Ama-bolts okuxekethile angadala ukuthi uhlaka lwehluleke noma lube yizingxenye zivinjelwe ngaphansi kwengcindezi. Ugongolo oluqhekekile lungavuka ngokuzumayo. Ukuvuza kwe-hydraulic kungaholela ekulahlekelweni kokungazelelwe kokulawulwa noma, ezimweni ezingavamile, ukusakazwa koketshezi oluphakeme olungangena esikhunjeni. Imodeli ye-kinetic ene-flywheel eyonakele noma igiya linamandla okuhluleka ukwehluleka okuyinhlekelele. Ngaphezu kwalokho, i-wedge ethambile noma eyonakele ingadala izinkuni zishaye noma zibuyise emuva ngokungahleliwe. I-valve yokukhishwa enamathelayo ingavimba i-opharetha ukuthi ibuyise isilinda ngendlela elawulwayo. Ngokunamathela enkambisweni eqinile yesondlo, awugcini nje ngokulondolozwa kwemishini yakho; Unciphisa ngenkani lezi zingozi. Yonke i-bolt eqinisiwe, zonke izithotho zamafutha, futhi yonke ingxenye ehlanziwe iyisinyathelo esiya ohlangothini oluhlaza okopela izinkuni. Lokhu kwenza isondlo hhayi nje udaba lwezomnotho, kodwa sibe nesibopho esiyisisekelo soMsebenzisi.

Ukusungula nokulandela inqubo yokugcina eguqukayo I-Manual Log Splitter Ingabe umkhuba olula kodwa ophumelela kakhulu. Kudinga isikhathi esincane nokutshala imali, ikakhulukazi uma kuqhathaniswa nezindleko zokulungiswa noma ukushintshwa. Le ndlela eyakhelwe izinsika zokuhlola ukusetshenziswa kwangaphambi kokusebenzisa, ukuhlanza kwangaphambi kokusetshenziswa, ukunakekelwa kwe-hydraulic yesikhathi nesikhathi sokunakekelwa kwemishini, kanye nokugcinwa okufanele, kuzoqinisekisa ukuthi ithuluzi lakho lihlala lingumlingani othembekile futhi ophephile iminyaka ezayo. Ukuqina kwe I-Manual Log Splitter Ungomunye wamaphuzu awo asemqoka, futhi lokho kuqina kutholakala ngokuphelele ngokuxhaswa ngenxa kanembeza. Ngokufaka le mikhuba, uvikela ukutshalwa kwemali kwakho, uthuthukise ukusebenza kwakho, futhi, okubaluleke kakhulu, uvikele inhlala-kahle yakho ngaso sonke isikhathi lapho uhlela izinkuni. $

see more

see more

see more

see more

see more

see more

see more

see more