I-Chrome Pliating, njengobuchwepheshe bokwelashwa okungaphezulu kwengaphezulu, ibeka ungqimba omncane wensimbi ye-chromium ngaphezulu kwenduku ye-cylinder ukuze wakhe ungqimba olunzima nolubunwe. Le ngqimba ye-chromium ayigcini ngokulukhuni kakhulu futhi ingamelana ngempumelelo nokugqoka kwangaphandle futhi inciphise ukulimala okungaphezulu okubangelwa ukungezwani; I-Chromium ibuye ibe nokuqina okuhle kwamakhemikhali futhi ingahlukanisa ngempumelelo ukuguguleka komoya, umswakama kanye nemidiya ewonakalisayo, ukuthuthukisa kakhulu ukumelana nokugqwala kwenduku ye-cylinder.

Inqubo ye-Chromium Plaving ifaka phakathi ukusabela okuyinkimbinkimbi kwe-electrochemical, kanye namapharamitha afana nokwakheka, izinga lokushisa, ukuqina kwamanje, nesikhathi seplifidi yesisombululo se-electroplating kudingeka ukuthi silawulwe ngokuqondile ukuze kuqinisekiswe ukufana okuhle nobukhulu be-coating. Isendlalelo se-chrome esezingeni eliphakeme angeke sithuthukise ukusebenza kwenduku ye-cylinder, kepha futhi sinikeze i-luster ekhanyayo futhi uthuthukise ama-aesthetics womkhiqizo. I-chromium ungqimba futhi inobuhlakani obuhle kagesi nobudlova, okuyibhonasi engeziwe yezinduku zesilinda kuzicelo ezithile.

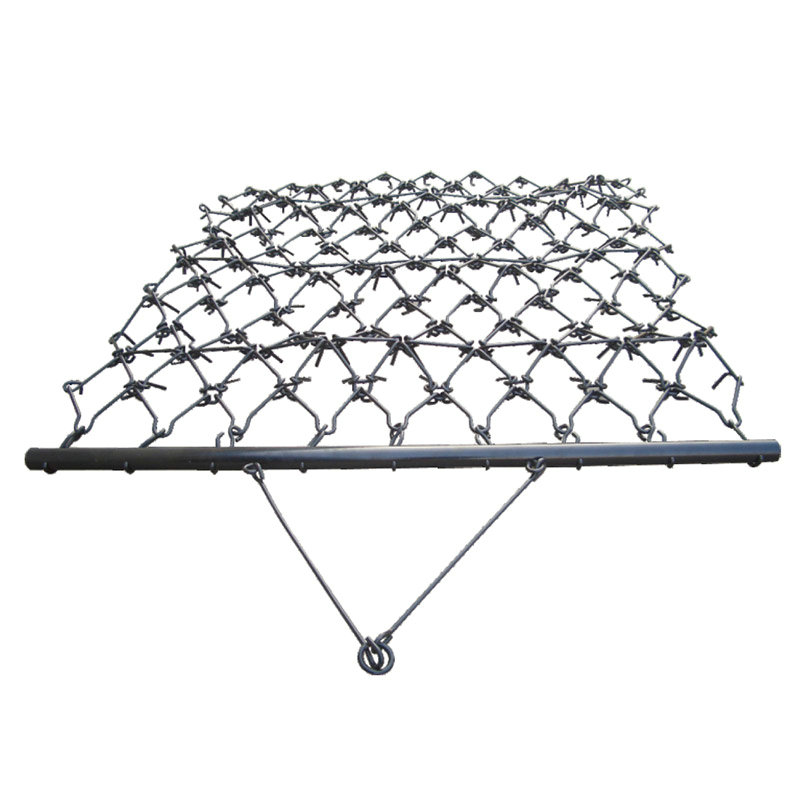

I-Shot Peening, njengobuchwepheshe obuqinisa ngokomzimba, isebenzisa i-jetting ephezulu yezinhlayiya zokudubula ukuba nomthelela ebusweni benduku ye-cylinder, okwenza ukuthi kuguqulwe ngopulasitiki kwezinto ezibonakalayo, ngaleyo ndlela kukhuphuke ubunzima bendawo yokuhlala kanye nokucindezelwa okusalelayo okucindezelayo. Le nqubo ingabeka kahle imifantu emincane ebusweni, yehlise ukugxila kwengcindezelo, futhi ithuthukise kakhulu amandla okukhathala futhi ugqoke ukumelana nenduku ye-cylinder.

Umphumela wokudutshulwa uncike kakhulu ohlotsheni, usayizi, isivinini somjovo kanye nesikhathi sokwelashwa kwesibhamu. Amapharamitha anengqondo wokudubula adubula angaqinisekisa ubulukhuni obuhle nokusatshalaliswa kobulukhuni endodeni ye-cylinde indawo, ngenkathi ugwema ukulimala okungaphezulu noma izinguquko ezibucayi ezibangelwa ukucubungula ngokweqile. Kuyaqapheleka ukuthi ukudutshulwa kwe-pening akunakuthuthukisa izakhiwo zemishini ze-cylinde induku, kepha futhi kuthuthukisa futhi i-morphology yayo ye-morphology ngezinga elithile futhi kuthuthukise ukuxhumanisa kwalo ngezimpawu zokuthambekela kanye nezithasiselo, ngaleyo ndlela kunweba impilo yenkonzo yesilinda.

Kuzinhlelo zokusebenza ezisebenzayo, i-chromium planing kanye nokudutshulwa kuvame ukungabi khona ekwahlukanisekayo, kepha sebenzisana ndawonye endongeni ye-cylinde indawo ngokuya ngezidingo ezithile zokuthuthukisa ukusebenza. Umgomo wezesayensi waleliqhinga lokwelashwa elihlanganisiwe ukuthi ungqimba we-chromium pluriating anikeza isithiyo esiqinile sokuvikela ngenduku ye-cylinder, ukumelana kahle nokuguguleka kwangaphandle; Ngenkathi kudutshulwa kuqinisa ububanzi benduku ye-cylinder, kuthuthukisa ubunzima bayo kanye nezakhiwo zokungakhathali. Ababili laba baphelelisa futhi bathuthukisa ngokuhlanganyela ekumelaneni nokugqwala nokugqoka kokuphikiswa kwenduku ye-cylinder, banweba impilo yabo yenkonzo futhi banciphise izindleko zokulungisa.

Le khasi I-Tie Cylinder Rod Lokho kuqala i-chromium-plated inesendlalelo se-chromium esilinganayo futhi esiminyene ebusweni bawo. Le Herser ye-Chromium ayigcini nje ngokuvikela izakhiwo ezinhle kakhulu zokuvikela, kepha futhi ihlinzeka ngesisekelo esihle sokwehla okulandelayo. Ngesikhathi senqubo yokudubula, umthelela wama-pellets ungaqhubeka uhlanganise ungqimba lwe-chromium, wenza amandla okubopha phakathi kwawo kanye nezinto ezisetshenzisiwe ezinamandla. Ngasikhathi sinye, umthelela wama-pellets nawo angakha imigodi emincane ebusweni bengqimba ye-chromium. Le migodi ingumgodi ingagcina uwoyela wokugcoba, ithuthukise ukusebenza kwe-lubrocation ye-cylinder rod, futhi inciphise ukungqubuzana nokugqoka.

Isu elihlanganisiwe lokucubungula le-chrome plating kanye nokudubulana kungathuthukisa kakhulu ukumelana nokukhathala kwe-cylinder rod. Ukucindezelwa okusele okucindezelwe okwenziwe ngesikhathi sokudubula kungasusa ukucindezelwa okuthe xaxa okutholwe yi-cylinder rod ngesikhathi sokusebenza, ngaleyo ndlela kubambezele ukukhiqizwa nokwanda kokungakhathali kwe-cylinder rod.

Emasimini okukhiqiza izimoto, ukukhiqiza imishini, i-aerospace kanye nezinye izinkambu, ama-cylinders e-Tie Rod asetshenziswa kabanzi futhi agxeka. Ukuthatha ukukhiqiza izimoto njengesibonelo, ukumelana nokugqwala nokuvikelwa kokuphikiswa kwenduku yesilinda kuhlobene ngqo nokusebenza nokuphepha kwezakhi ezisemqoka ezifana nohlelo lokuqhuma kwezimoto kanye nohlelo lokuqondisa. Izinduku zezilinda ezisebenzisa inhlanganisela ye-chrome plating kanye nokudutshulwa kwe-pening akunakuthuthukisa ukuqina kwalezi zingxenye, kepha futhi kunciphisa izindleko zokulungisa ezibangelwa ukwehluleka futhi zithuthukise ukuthembeka nokuphepha kwayo yonke imoto.

Emkhakheni wokukhiqiza imishini, ukuqina kokusebenza kwenduku ye-cylinder kubalulekile ekusebenzeni okuqhubekayo komugqa wokukhiqiza. Ukusetshenziswa kwezinduku zesilinda ze-cylinder ne-lylinder ne-shot

Isu elihlanganisiwe lokucubungula le-Chrome Plating kanye ne-Shot Peening lingaletha futhi ukuvikela imvelo kanye nezinzuzo zokonga amandla. Ngakolunye uhlangothi, ungqimba olusezingeni eliphezulu lwe-chromium planing lunganciphisa ukungqubuzana nokugqokwa kwenduku yesilinda ngesikhathi sokusebenza, ngaleyo ndlela kunciphise ukusetshenziswa kwamandla; Ngakolunye uhlangothi, ama-pellets akhiqizwa ngesikhathi senqubo ye-Shot Peening angavuselelwa, anciphise imfucuza yezinsiza kanye nokungcoliswa kwemvelo.

see more

see more

see more

see more

see more

see more

see more

see more